(1)Research of Digital Diesel Engines

“Fast Maneuver, Global Combat” is the development direction of our military equipment in future. The development of high-compact and auto-adaptive military power system is the urgent need of our military ground maneuver equipment. The discipline has presided over the development of a digital diesel engine for the new generation of the ground maneuver weapon platform. Since 2011, many rounds of technical breakthrough, bench examinations, various environments experiments, and real-road durability assessments were completed after prototype development, engineering exploitation, crafts improvement, reliability research, and construction of quality assurance system. The diesel engine, with good performance, has already been equipped for the troops to trial run.

(2)Establishment of Internal Combustion Engine Design System

From 2012 to 2015 period, Beijing Institute of Technology, as deputy director, undertook the research work of Basic Product Innovation Plan for Military Vehicle Powertrain, and completed more than 10 major projects such as high density combustion theory and test technology system, digital management technology and verification platform for overall operating condition, high speed and high load engine structure theory and simulation platform. Beijing Institute of Technology designed more than 100 key technical specifications such as high speed diesel engine piston connecting rod crankshaft design, advanced propulsion system integrated control strategy and software design, developed more than 50 core hardware and software platforms such as software of lubrication system performance, test bench for fretting fatigue in internal combustion engine . All of these achievements have been successfully applied in the R & D technology system for armored vehicle powertrain industry.

(3)Turbocharger Serialization Design and Testing Technology

The technology was developed to fit the requirements of the engine power density enhancement and emission control. Based on the thorough fundamental research on the flow mechanism and flow control methods in turbocharger, we have developed CAE/CFD based integrated turbocharger predicting-design and matching system with complete independent intellectual property rights. The system has been used for developing serials of turbochargers in many domestic turbocharger manufactures. Flow and performance testing technologies on turbocharger and small size turbomachinery and its components were also studied and corresponding testing facilities were developed. Several developed testing systems, such as the “Auxiliary-turbocharger Power-Consumption Based Turbine Performance Testing Method and Facility”, “Turbocharger Leakage Flow Testing Method and Facility” and “Turbocharger Thermal Shock Test Facility” filled the gap in corresponding turbocharger testing fields. The achievements in the turbocharger and small turbomachinery design and testing were awarded for the second prize of Ministry of Education of China.

(4)Integrated Electronic Control and Management System

As early as the early 90s of last century, Beijing Institute of Technology had started the research of electronic control technology of gasoline engine and diesel engine. In 1993, a multi-cylinder integrated control system of gasoline engine with multiple functions of fuel injection, ignition and idle speed control was developed with independent intellectual property rights. In 2003, the first set of PCM was developed in China. In 2010, the first armored vehicle integrated control system was developed. A light tank diesel engine integrated electronic management system developed in 2016 achieved the eight EUP independent control, performance optimization, regulation, state control and emergency treatment, had an adaptive function, to ensure the efficient operation of the engine under all-weather, and has been successfully applied to a new type of light tank.

(5)Strength and Reliability Analysis of Internal Combustion Engine

Beijing Institute of Technology is in charge of or participates in nearly all the work of design evaluation for the main parts of armored vehicles such as tank, infantry fighting vehicle, amphibious assault vehicle, self propelled artillery, wheeled armored vehicle and so on. This work plays an important role in ensuring the development of related products. Meanwhile, we participate in the strength and reliability analysis for several kinds of rocket engines. Beijing Institute of Technology is leading the way in analyzing strength of high mechanical load-carrying parts such as crankshaft and cylinder block, high thermal load-carrying parts such as cylinder head and piston for internal combustion engine in China.

(6)New Concept and Novel Power System Development

Facing the future development direction of military power system, Beijing Institute of Technology carried out the research work bout electric drive and hybrid power of military vehicles、hydraulic free piston diesel engine integrated propulsion system and small car gas turbine, and carried out systematiclly the research and development about hydraulic free piston engine、hydrogen IC engine、free piston internal combustion generator, then explored the technological approaches for new concept and new energy power system.

The hydraulic free piston diesel engine is a new concept power system integrated with reciprocating piston internal combustion engine and plunger hydraulic pump. The stable operation of the prototype has been successfully realized, the power of single cylinder is 15kW, and the indicated thermal efficiency is over 40%.

Hydrogen IC engine is a new type of internal combustion engine developed entirely based on the characteristics of hydrogen fuel. Beijing Institute of Technology has developed the first prototype of hydrogen engine in China, which has accumulated over 10,000 km.

(7)Establishment of Emission Regulations for IC Engines

Beijing Institute of Technology’s Laboratory of Automotive Power and Emission(LAE) is the chairman unit of United Nations UNECE WP29 Vehicle Indoor Air Quality standards (VIAQ), as well as one of major unit responsible for national emission control strategies and regulations. LAE has presided over or participated in establishment of 14 national and regional vehicle emission regulations, including new-developed vehicle certification and in-use vehicle regulations. These regulations include "Emission standards and limits for in-use gasoline vehicles (GB18285-2005 revision)", "Emission limits and measurement methods for in-use vehicles equipped with diesel engine(GB3847-2005 revision)", " Limits and measurement method for exhaust pollutants from vehicle equipped with ignition engines by remote sensing". Especially, the" Technical Guide for Non-road machine Pollution Sources Emissions Inventory Compilation "compiled in 2014 has become the key document for guiding the preparation of the list of non-road machine pollutant emission sources in China. LAE has provided technical support work for vehicle emission standards establishment and revision of Beijing, Guangdong, Tianjin, Hainan, Inner Mongolia and other provinces and cities in China.

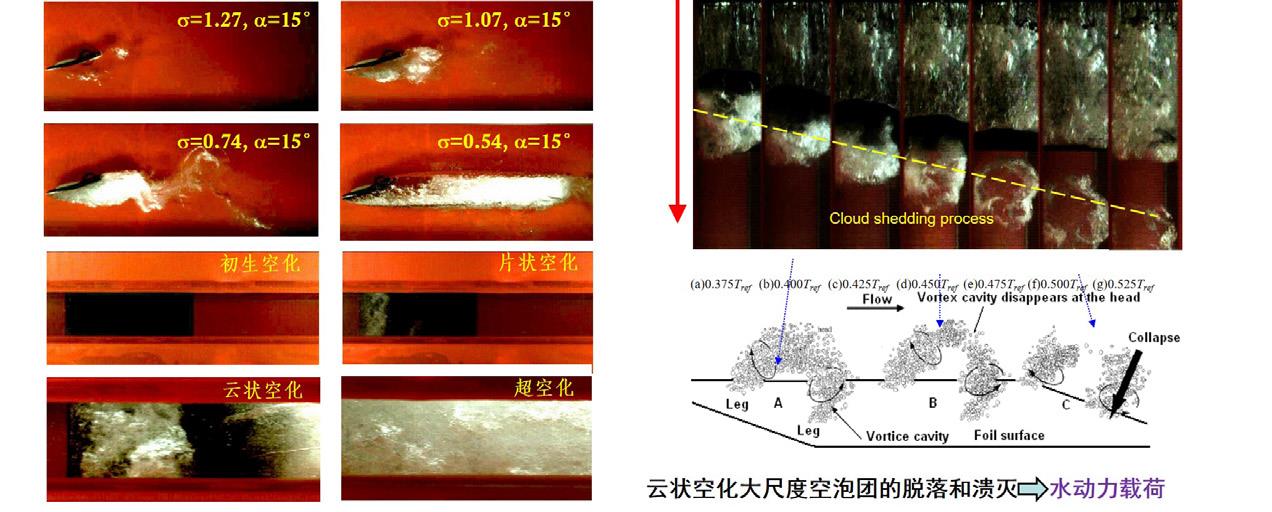

(8)Numerical and Physical Investigation of Cavitation and Supercavitation

We have various research equipments, including the high-speed cavitation tunnel, the test bench of hydraulic machinery, the water-entry/exit launch platform, the single bubble cavitation system, and the cryogenic cavitation tunnel, which provide high speed visualization and high speed flow field measurement of different types of cavitation phenomenon. We have developed different numerical models for unsteady cavitation, ventilated cavitation, supercavitation, compressible cavitating flow, cryogenic cavitation, and cavitation-structure interaction, which have been successfully applied to the research of the national defense weapon equipment, such as the drag reduction of the high-speed amphibious vehicles, the simulation of multiphase cavitating flow around the submarine-launched missile, and the high-fidelity prediction and optimization design of the liquid rocket engine turbopump. Based on the above research work, we have published more than 80 high-level journal papers, among which the highest citation rate for one paper is more than 140 times. We have also received more than 20 invention patents and more than 20 software copyright. Moreover, we have obtained 8 ministry-level science and technology awards.