Founded in September 2011, there are 6 full-time teachers in the Laboratory of Fluid Mechanics and Engineering, including 1 professor, 4 associate professors, and more than 30 graduate students. With the support of the Project 985, Project 211 and the research platform for power engineering, we have state of art instrumentations and high-performance computing devices. The main interest of our laboratory is hydrodynamics, with focus on the cavitation. Abundant experience has been accumulated during the research process, such as the load analysis of the water-exit cavity, prediction of the motion of supercavitating vehicle, prediction of the cavitation performance of the liquid rocket engine inducer, supercavitating flow mechanism, water jet propulsion, and underwater drag reduction.

Research areas

The researrch areas includes cavitating and supercavitating flow mechanism, Multiphase hydrodynamics and advanced marine equipment, Hydraulic machinery and system, Thermal fluid dynamics in energy and power system etc.

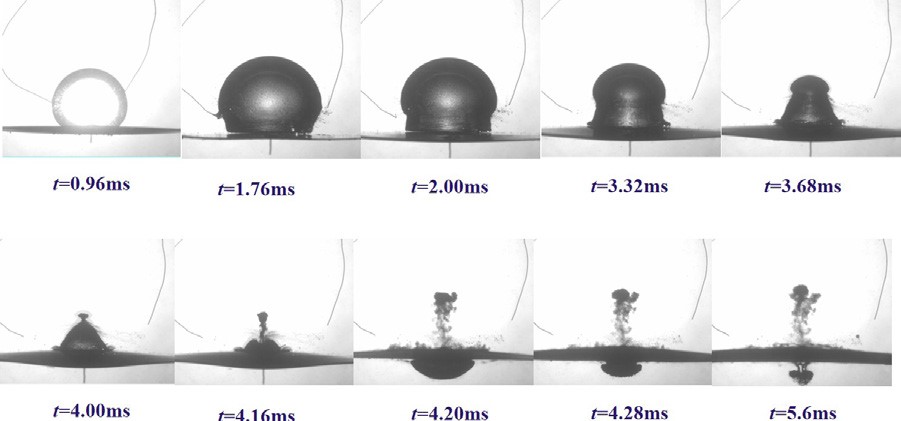

Figure 1: Cavitating flow mechanism

Figure 2: Bubble dynamics

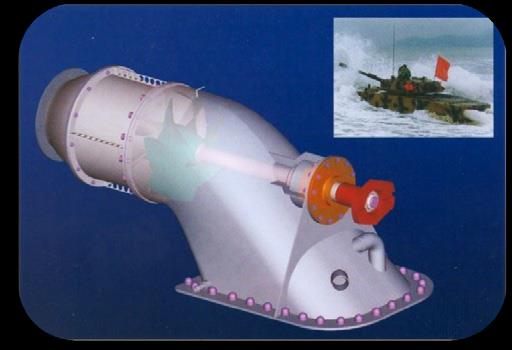

Figure 3: Advanced marine equipment

Research outomes

The new turbulence and cavitation models have been established for improvement of the prediction accuracy of cavitation, which have been mainly applied to various engineering fields.

(1) The underwater drag reduction technology, accompanied with the related patent, has been applied to the equipment transformation of the amphibious vehicles;

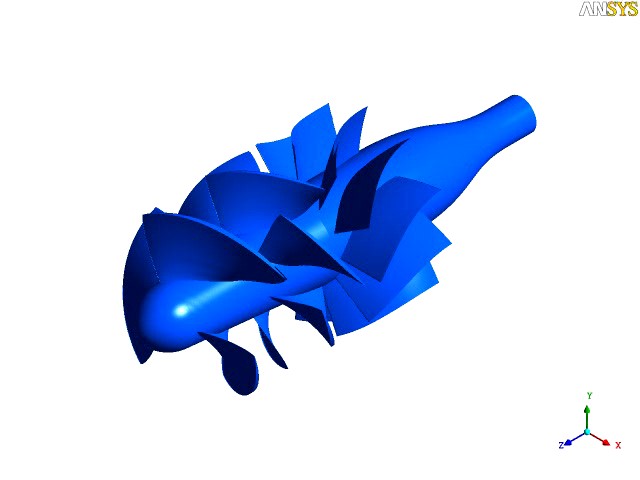

(2) The design software for high-speed turbopump has been applied to the optimization of the launch vehicle engine turbopump for improvement of the cavitation performance;

(3) The medium model for fuel has been adopted in the prediction and optimal design of the aero-engine fuel pump;

(4) The pumps have been developed based on the energy-efficient hydraulic models and widely used in the city’s sewer system and flooding control system.

Figure 4: The amphibious vehicles

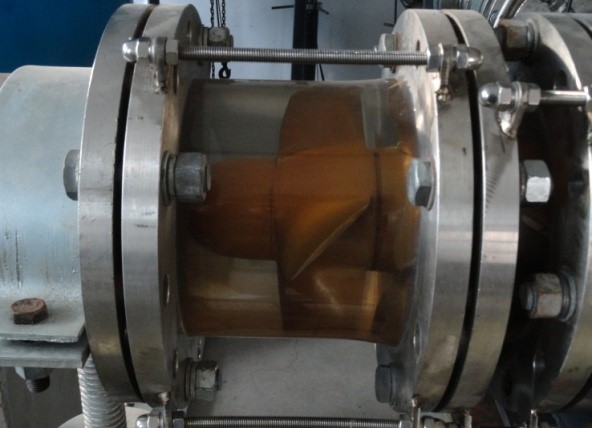

Figure 5: High-efficient hydraulic models

Main support condition

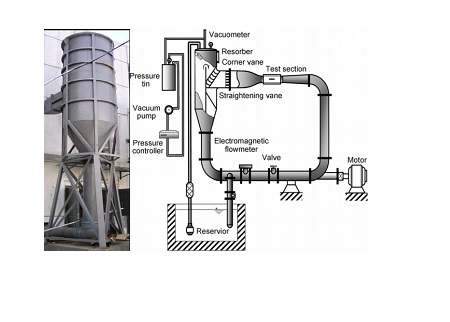

There are state of art instrumentations, including the high-speed cavitation tunnel, the test bench of hydraulic machinery, the single bubble cavitation system, the cryogenic cavitation tunnel, the high-speed Particle Image Velocimetry, and the high-performance computing devices.

Figure 6: Closed-loop cavitation tunnel

Figure 7: Cryogenic cavitation test platform